Sponge Iron

Direct reduced iron (DRI), also called sponge iron, is produced from the direct reduction of iron ore (in the form of lumps, pellets, or fines) to iron by a reducing gas or elemental carbon produced from natural gas or coal. DRI is most commonly made into steel using electric arc furnaces to take advantage of the heat produced by the DRI product. Direct-reduced iron has about the same iron content as pig iron, typically 90–94% total iron (depending on the quality of the raw ore) so it is an excellent feedstock for the electric furnaces used by mini mills, allowing them to use lower grades of scrap for the rest of the charge or to produce higher grades of steel.

Overview

Sponge iron is formed through the reduction of iron ore to metallic iron through reaction with carbon in the form of coal, etc. at approx. 1100 degree Celsius. Sponge iron is also referred to as direct reduced iron, metalized iron, or hot briquetted iron.

Sponge iron is used in the iron and steel industry as a substitute for scrap in induction and electrical arc furnaces. Over the years, the shortage of expensive melting scrap has made sponge iron a significant raw material for manufacturing high quality steel. In iran, the abundance of Iron Ore deposits has led to absorption of the renowned by the iran industry and use of ore lumps and fines has led to the country becoming the largest producer of sponge iron in the world.

JISPL ventured into this segment in early nineties and over the years has perfected the technology and become the second largest sponge iron manufacturer in iran .

Advantage

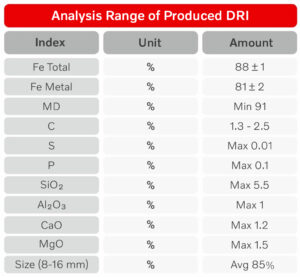

JSWAION possesses considerable expertise in the manufacture of sponge iron. The sponge iron exhibits superior quality characteristics with excellent metallic content and an impeccable consistency in chemical and physical characteristics and low sulphur and phosphorus content. The production process also ensures that the sponge is free from dust caused during material handling.

Specification

Supply Condition:Sponge Iron may be supplied in Lumps or as Fines either in loose or bagged in HDPE bags, as may be required by the customer.

Standard:As per BIS: 15774, 2007

Material Specification:Note : Above size tolerance is valid at dispatch end only.

Storage Precautions Needed:It is advisable to keep Sponge Iron under cover to avoid any direct contact with moisture before usage. Moisture promotes oxidation thus reduces metallization.

Sponge Iron needs special care during storage and transportation for which IS:10852 stipulations may be followed.

Special care is taken while dispatching Sponge Iron from plant by putting proper sealing over the material loaded on vehicles to protect against environmental deterioration.

Related products

150×150 Iranian Steel Billet (12m) | Buy at Best Price

Exported steel beam price iranian

Iron beams are one of the most widely used profiles in the construction industry. This profile is made of steel and allows the construction of very strong metal structures. Iran is one of the leading countries in the production of this product. Today, Iran's iron beams can be exported to many Asian and even European countries and are one of the best ways to bring foreign exchange into the country. If you are interested in exporting this valuable product, trading and earning money in this field, we have shared some useful information with you below.

Reviews

Clear filtersThere are no reviews yet.